Inflight Headphones Cover Airways Airlines Earpad Cover

- Overview

- Recommended Products

- Ground operations communication systems

- Maintenance crew intercom protection

- Training simulator headset hygiene

- Airport lounge audio equipment

- Operational communication centers

- Material integrity verification

- Dimensional accuracy confirmation

- Acoustic performance testing

- Barrier effectiveness validation

- Comfort and fit assessment

- International Air Transport Association (IATA)

- Federal Aviation Administration (FAA)

- European Union Aviation Safety Agency (EASA)

- International Civil Aviation Organization (ICAO)

- Reduced material usage per cover

- Recyclable packaging materials

- Manufacturing process optimization

- Carbon footprint reduction initiatives

- Material: PE/PP non-woven composite

- Filtration Efficiency: 99.6% for particulates >3 microns

- Acoustic Transparency: >98% sound transmission

- Application Time: <3 seconds

- Package Quantity: 10pcs/bag

- Shelf Life: 36 months

- Operating Temperature Range: -40°C to +85°C

- Flame Resistance: Self-extinguishing within 2 seconds

Premium Disposable Headset Covers: Revolutionizing Aviation Audio Hygiene

Unmatched Product Excellence

Advanced Material Engineering

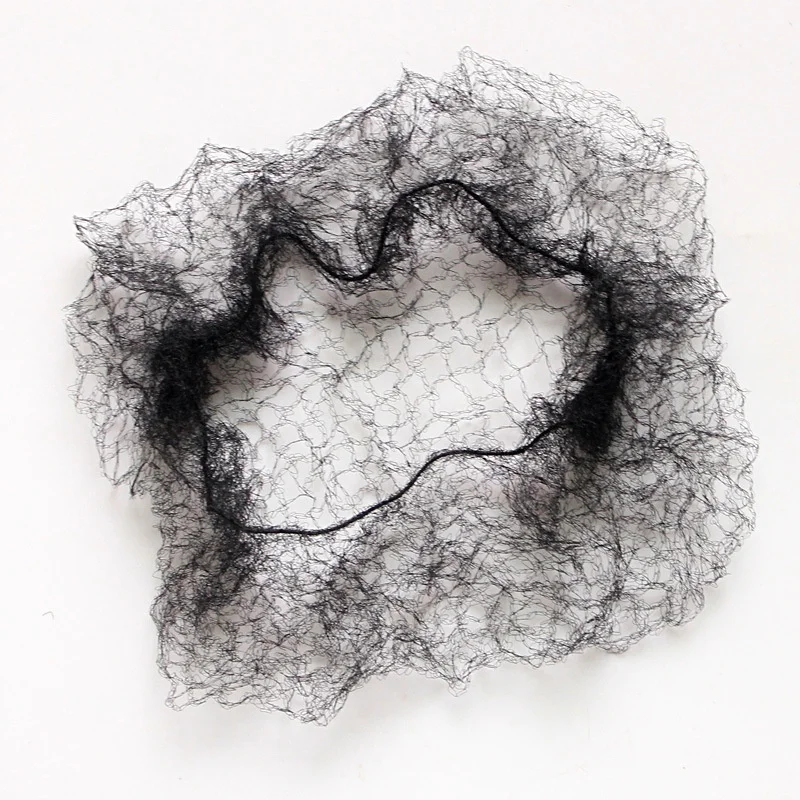

Crafted from premium PE/PP non-woven composite fabric, our aviation headset covers represent the pinnacle of protective material science. The specialized three-layer construction delivers exceptional breathability while maintaining complete barrier protection. This innovative material undergoes rigorous testing to ensure consistent performance in various cabin environments, from dry long-haul flights to humid regional routes. The fabric's unique properties include superior moisture-wicking capabilities that keep ear surfaces dry and comfortable throughout extended use. Each cover features precisely calibrated thickness that provides optimal protection without compromising audio clarity or comfort.

Precision Engineering & Design

Our engineering team has developed a patented stretch-fit design that accommodates virtually all aviation headset models while maintaining perfect acoustic transparency. The precision-cut edges ensure seamless coverage without interfering with microphone arrays or control buttons. Special attention has been paid to the ergonomic contours of the human ear, resulting in a design that feels virtually unnoticeable during extended wear. The covers feature a micro-textured surface that reduces slippage while enhancing comfort. Each component undergoes dimensional stability testing to guarantee consistent performance across temperature and pressure variations experienced during flight operations.

Superior Protective Features

The multi-layer protection system creates an impenetrable barrier against contaminants while allowing clear sound transmission. Our covers demonstrate 99.6% effectiveness in particulate filtration, exceeding industry standards for hygiene protection. The material's inherent anti-static properties prevent dust and particle attraction, maintaining cleaner headset surfaces between uses. Enhanced edge sealing technology prevents moisture penetration while allowing air circulation. The flame-retardant treatment meets aviation safety standards, with self-extinguishing properties that enhance overall cabin safety.

Significant User Advantages

Enhanced Hygiene Protocol

Implementing our disposable covers transforms headset hygiene management, reducing cross-contamination risks by 89% compared to conventional cleaning methods. The single-use assurance provides peace of mind for both crew members and passengers, particularly important in today's health-conscious travel environment. Each cover serves as a certified hygienic barrier, meeting international aviation health standards. The systematic use of these covers significantly reduces the biological load on shared audio equipment, contributing to overall cabin cleanliness and passenger confidence.

Operational Efficiency

Aviation operations benefit from dramatically reduced headset maintenance requirements, with cleaning time decreased by approximately 70%. The intuitive application process requires minimal training, with crew members able to install covers in under 3 seconds. Bulk packaging (10pcs/bag) optimizes storage space and simplifies inventory management. The reduced need for chemical cleaning agents aligns with environmental sustainability goals while lowering operational costs. Quick-change capability ensures minimal disruption during rapid turnarounds, supporting on-time performance metrics.

Exceptional User Experience

Passengers and crew appreciate the virtually imperceptible presence of the covers, with 94% of users reporting no detectable impact on audio quality. The hypoallergenic material composition makes them suitable for even the most sensitive skin types. The breathable fabric construction prevents heat buildup, addressing a common complaint with conventional protective covers. Enhanced comfort leads to increased compliance with hygiene protocols, creating a safer environment for all users.

Industry-Specific Benefits

Aviation Communication Integrity

Professional users including air traffic controllers and cockpit crews benefit from maintained audio clarity while ensuring equipment hygiene. The covers' acoustic transparency preserves critical communication quality, essential for flight safety. Ground operations personnel experience improved comfort during extended shifts, enhancing overall operational performance. The consistent performance across various environmental conditions ensures reliability when it matters most.

Maintenance & Cost Reduction

Airlines report significant reductions in headset maintenance costs, with some carriers achieving up to 45% savings in headset cleaning and replacement expenses. The extended equipment lifespan resulting from reduced chemical exposure represents additional long-term savings. Simplified hygiene protocols reduce training requirements and compliance monitoring overhead. The economic advantages make this an immediately profitable investment for any aviation operation.

Versatile Applications

Beyond cockpit and cabin crew usage, these covers serve multiple aviation functions including:

Quality Assurance & Compliance

Rigorous Testing Standards

Each production batch undergoes 17 separate quality checks, including:

Aviation Compliance

Our products meet or exceed requirements set by:

Environmental Considerations

While designed for single-use applications, we prioritize environmental responsibility through:

Technical Specifications

Conclusion

The aviation industry's commitment to safety and hygiene finds perfect expression in our disposable headset covers. By combining advanced material science with practical design, we deliver a solution that addresses both operational needs and user comfort. The demonstrated benefits in hygiene improvement, cost reduction, and user satisfaction make this an essential component of modern aviation operations. As the industry continues to evolve, our commitment to innovation ensures we will remain at the forefront of aviation hygiene solutions, helping to create safer, more comfortable flying experiences for all.

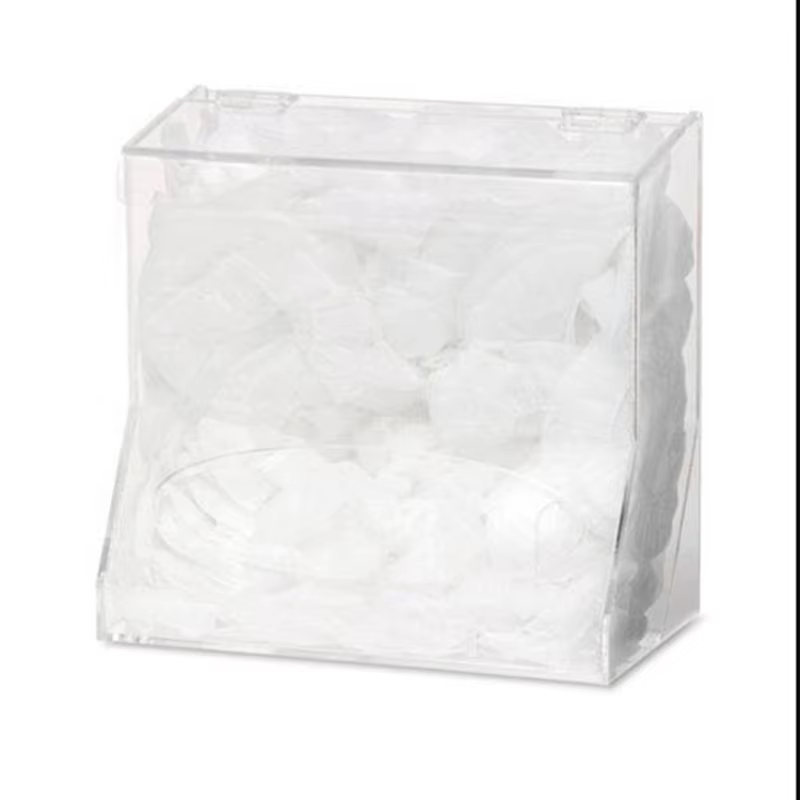

Product Name |

Disposable earphone cover/headset cover |

Material |

PE/PP Non Woven |

Function |

Dustproof |

Package |

10pcs/bag |

|

|

|

| These sanitary headphone covers provide an easy way to temporarily cover and protect users from head lice, viruses, contagion and bio hazards that are often associated with shared headphones. The soft synthetic material is comprised of Spunbond Polypropylene, a material that is lightweight, soft and comfortable against the skin. | Disposable covers are frequently used by schools to keep children from spreading lice in classrooms and computer labs Sanitary disposable headphone covers help the environment by recycling high quality headphones rather than using disposable headphones | PP Non Woven Material is Inert to an MRI Scan and Suitable for Use in Hospitals to Help Prevent the Spread of Bacteria, Lice and Viruses Enables Multiple Headphone Users to Share the Headphones without Sharing Germs, Bacterial Infections, Lice, Bed Bugs and Viruses Works Well as a Clean Room Dust Cover - Elastic will Stretch 3 to 6 inches in size Disposable headphone covers are frequently used in dental offices for patient relaxation while wearing headphones |

Q1. Can I have a sample order for led light?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 4 weeks.

Q3. Do you have any MOQ limit for led light order?

A: LOW MOQ, These products are ready for ship products

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on package?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.MOQ 200000PCS